Interesting Facts

The 3D SuPor® Ear enables the creation of a realistic 3-dimensional ear that reflects the patient’s own anatomy. This extraordinary procedure was developed in 2018 in a joint project between Dr. Sheryl Lewin and the Poriferus Company and became known as “3D Lewin Ear” or “PIER.”

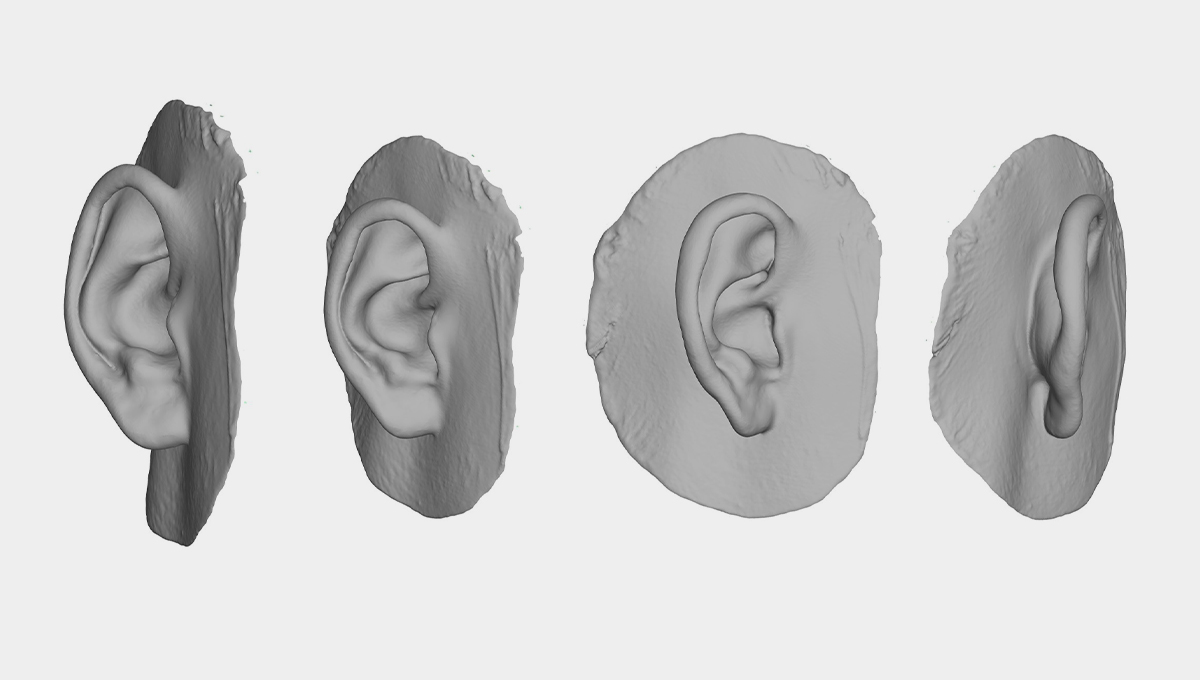

3D-Scan

We use a high-resolution 3D scanner based on blue light technology to create a precise three-dimensional image of the patient’s natural ear. It is a simple and painless examination that is performed in a few minutes with the patient awake.

Patient-specific ear implant

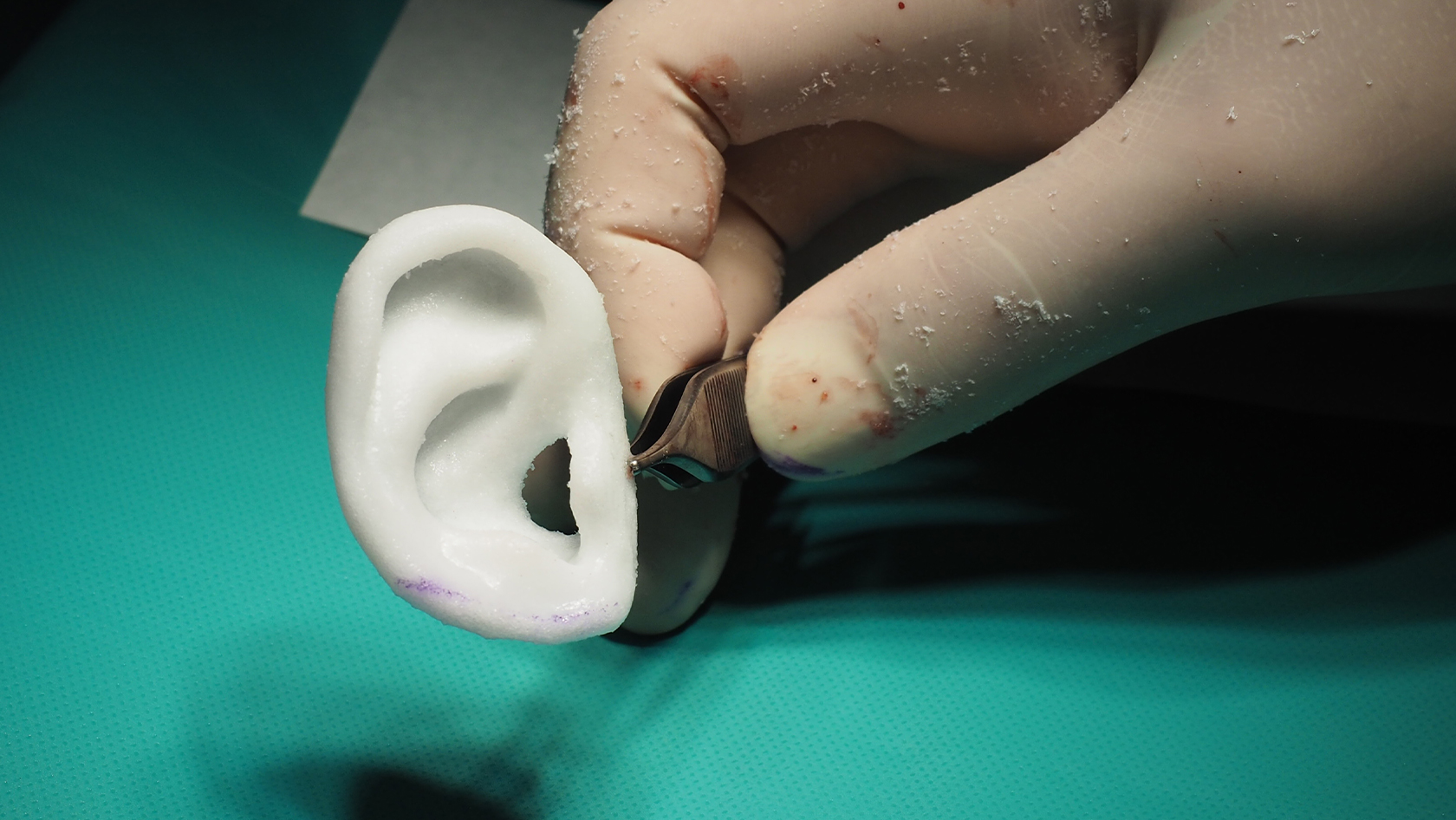

The final 3D ear design is then sent to Poriferous, where the digital data is converted into a patient-specific, sterile implant. Using this unique FDA- and EU-approved process, the ear implant is made from a single piece of high-density, porous polyethylene. The one-piece design creates a highly realistic and very stable implant.

Its special material properties and flexibility significantly reduce the risk of fracture compared to conventional two-piece polyethylene implants. Further details are then incorporated into the implant in the operating room.

Operation

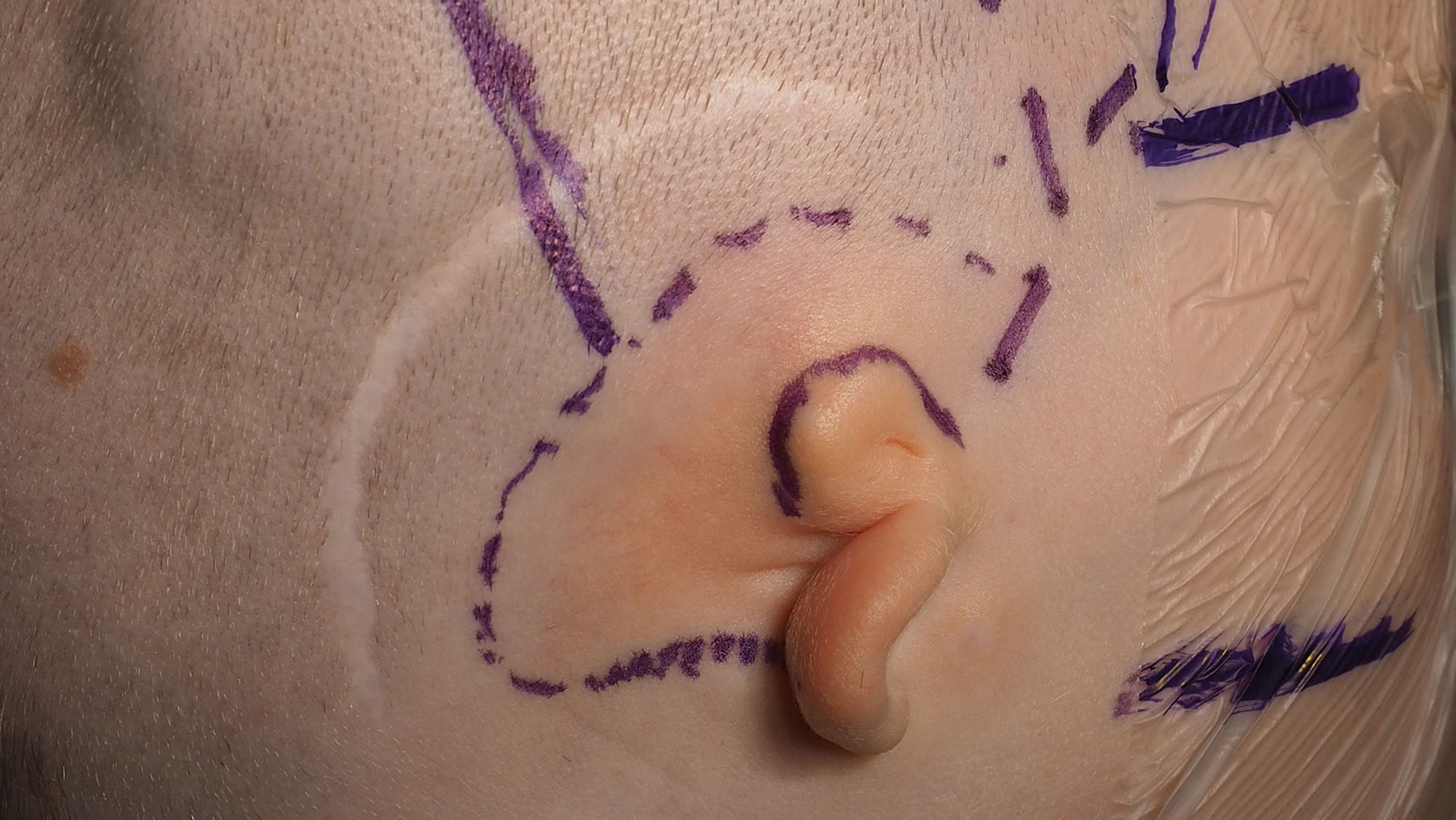

Crucial to the success of the operation is the creation of a reliable soft tissue mantle of the patient’s own tissue. A living membrane is needed to cover the polyethylene. This so-called temporalis fascia flap (TPF) is located between the skull bone and the scalp and is interspersed with blood vessels and nerves.

The TPF is carefully exposed during surgery and then placed around the one-piece implant and suctioned to achieve the exact shape of the ear implant.

The flap grows into the pores of the implant and provides nutrients to the overlying skin. Free skin grafts are then used to provide coverage. The skin grafts are taken from the back of the healthy ear and/or the inside of the upper arm. Removal of the flap is usually unproblematic because there are several other layers of tissue beneath the flap. Only fine line-shaped scars are left behind where the skin is removed.

This demanding technique requires a high degree of skill and extensive experience in order to deal flexibly with the difficult anatomy. The TPF flap is so thin that it is translucent. Only a flawless, perfect flap allows the detailed 3D implant to be fully appreciated. Preparation of this flap has been a standard procedure of mine for over 15 years as part of other reconstructive techniques.

Aftercare

In the first weeks after surgery, the ear is still sensitive to activities, injuries as well as infections and requires good protection and especially careful care. We will instruct you in detail about this.

During the first week after surgery, the ear will be covered by a permanent bandage that does not need to be changed. This will be removed after one week and you will be able to see the new ear for the first time. After that, a permanent dressing will be applied again if necessary, or daily dressing changes will already take place. After two weeks, the skin grafts are intensively cleaned and crusts are removed.

Durability

The use of porous polyethylene for ear reconstruction began in 1982. Since then thousands of such surgeries have been performed worldwide without any problem with the polyethylene material itself, such as an immune reaction (rejection) or allergy.

The use of an individual, one-piece and flexible implant avoids most of the known disadvantages of the previously used polyethylene implants, for example the tendency to break.

After about 6 weeks, the critical phase of wound healing is over and there are no more restrictions regarding physical activities. Nevertheless, it takes several months until the swelling has completely subsided and the final shape and skin texture of the new ear is achieved.

The longevity of this reconstruction results from the ingrowth of tissue, blood vessels and nerves into the porous basic framework within the first weeks after surgery. The porous polyethylene thus carries endogenous tissue both inside and as an outer shell. Therefore, the immune system has access to the reconstructed ear and can resist infections as well as minor injuries. The 3D SuPor® ears are made to last a lifetime. However, should a problem occur, the framework can be replaced.